Machine Learning

This is a subset of AI that gives machines the ability to learn from data. It automates the creation of analytical models, allowing systems to learn from data, identify patterns, and make decisions.

Deep Learning

Deep learning is a subset of machine learning. It sets basic parameters on data and trains the computer to learn independently by recognizing patterns using many layers of processing. It is useful for image and speech recognition.

Natural Language Processing (NLP)

NLP enables machines to understand, interpret, and generate human language. It is used for language translation, sentiment analysis, and speech-to-text conversion.

Computer Vision

Computer vision enables machines to interpret and understand visual information from images or videos, for tasks such as image classification or facial recognition.

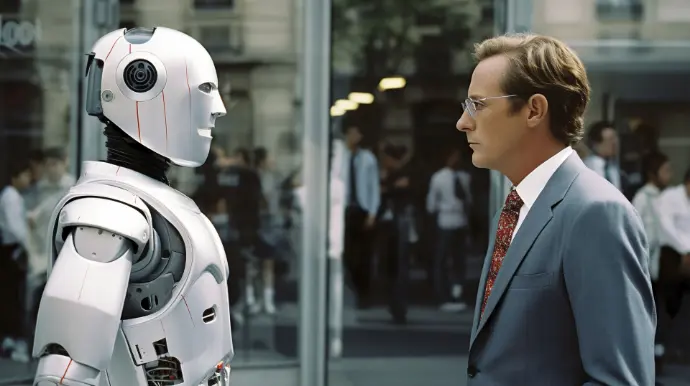

Robotics

Robotics combines artificial intelligence with mechanical engineering to create machines (robots) capable of performing tasks autonomously or with minimal human intervention. This includes industrial robots used in manufacturing, as well as social robots designed for human interaction.

Now that you know the underlying technologies, let's look at how AI solutions are implemented and how they improve efficiency and innovation in the manufacturing sector.

IHRO NEWS

IHRO NEWS